- News Center

Company news

Company news Industry information

Industry information

- Stainless steel 06

- Stainless steel 07

- Stainless steel 05

- Stainless steel 03

- Stainless steel 04

- Stainless steel 01

- Stainless steel 02

- Aluminum castings 05

- Aluminum castings 04

- Aluminum castings 03

- Aluminum castings 02

- Aluminum castings 01

- Aluminum die-casting product 08

- Aluminum die-casting product 07

- Aluminum die-casting product 06

- Aluminum die-casting product 05

Industry information

Position:Home > News Center > Industry information

- The joint parts of the body frame are mostly aluminum alloy castings

- Editor:Hangzhou Hongcheng Pml Precision Mechanism LtdDate:2016-05-30 10:45 Click:

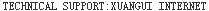

the manufacturing technology of aluminum alloy body frame structure is a core technology of Audi, which has been studied and developed for up to 20 years in this field. Its body frame is composed of cast and hydroforming aluminum alloy components, including 35% high precision aluminum alloy castings, 22% extruded aluminum alloy parts, and 35% aluminum alloy plates. Among them, the connecting parts of the body frame are mostly aluminum alloy castings. This kind of aluminum casting plays the role of connecting the aluminum materials of the body. It is the main bearing component and requires a high strength. In order to meet the needs, the body aluminum alloy castings are mostly complex thin-walled structures. Because of the structural characteristics of such castings, as well as vehicle

The traditional foundry technology has been unable to meet the requirements of mass production in the industry. The new extrusion casting technology, such as vacuum pressure casting and special extrusion casting, is mostly used in the manufacture of aluminum alloy body castings abroad.

Vacuum pressure casting and special squeeze casting are new casting technologies. Vacuum pressure casting, compared with ordinary die-casting, increases the vacuum operation. It can pump gas out of the cavity and fill the cavity in the vacuum state. The gas can be reduced. The casting can be heat treated. The mechanical properties of the casting are higher than that of the common die casting.

Special extrusion casting can not only achieve liquid metal extrusion molding but also realize semi solid metal slurry extrusion molding. The slurry has good fluidity and spherical microstructure, can form more complex castings, and the castings have excellent mechanical properties and higher near final molding degree.

The above two special casting processes have high production efficiency and are very suitable for large-scale production in the automotive field. Because of the above advantages, foreign auto manufacturers have applied these two foundry technology to the development and production of aluminum alloy body, and have achieved good application results.

From the experience of developing the aluminum alloy body of the foreign automobile manufacturers, the vacuum pressure casting and the special extrusion casting technology are the important key technologies and also one of its core technologies. In order to carry out the research work of the aluminum alloy body in our country, the two kinds of foundry technology must be mastered. However, the time of carrying out the two kinds of casting technology in China is relatively late, and a series of common technical problems, such as alloy materials, process control, die design and equipment development, have not been studied in depth. In addition, the research on vacuum pressure casting and special extrusion casting is relatively scattered at home and abroad, and the equipment is relatively simple. There is no multi-functional equipment to realize the two casting processes at the same time, and the integrated production of aluminum alloy body castings can not be realized, which brings more difficulties to the centralized purchase of automobile manufacturers. Therefore, it will become an important work for the research of the manufacturing technology of aluminum alloy body in China to develop a multi-functional compound compression casting equipment which can simultaneously realize the above casting process and carry out the research on the common technology of key castings of the aluminum alloy body. The article comes from Baidu.